Descripción del Producto

H2 V2S

Doble engranaje | Transmisión directa | Elección rentable

195 g de peso ligero

Soporte 270 ℃

Doble engranaje 7:1

Nivel de ahorro de mano de obra

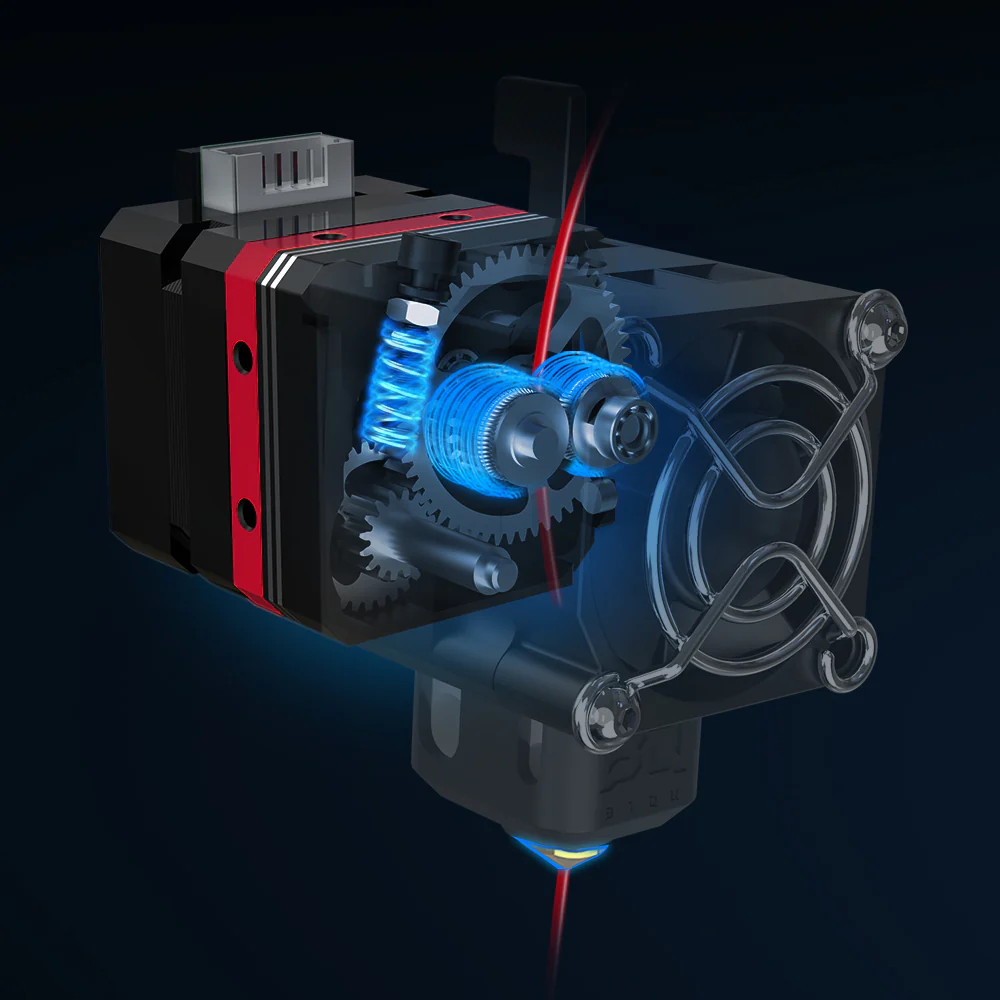

Ligero y compacto

Peso ligero, baja inercia, mejor precisión posicional.

Artesanía exquisita

El cuerpo de aleación de aluminio 6061 T6 garantiza un rendimiento duradero incluso en condiciones extremas.

Alimentación de filamentos más sencilla

La palanca del interruptor mejorada libera tus manos al alimentar.

Disipación de calor eficiente

Diseño del disipador térmico optimizado para mejorar la disipación del calor, evitar la fluencia del calor y garantizar una vida útil más larga del extrusor.

Potente sistema de extrusión

Doble engranaje y una relación de transmisión de 7:1 para una fuerza de empuje excepcional.

Ideal para filamentos flexibles

Ajuste el tensor del tornillo para adaptarse a diferentes tensiones del engranaje impulsor y mejorar la impresión con filamento flexible.

Impresión a alta temperatura

El disipador térmico bimetálico permite la impresión a alta temperatura a 270 ℃ con una funda de silicona como aislamiento.

Compatibilidad perfecta

Compatible con numerosos materiales, desde PLA y ABS hasta TPU, Nylon y PETG.

Qué hay en la caja

El kit completo H2 V2S incluye un extrusor premontado, un ventilador de refrigeración, cables, tornillos y otras herramientas para instalarlo en la impresora 3D.

Dimensiones y especificaciones

Método de extrusión

Extrusión de doble engranaje

Temperatura máxima de impresión

270℃

Peso

195 g (incluido el cartucho calefactor, el termistor y el ventilador)

Fuerza máxima de extrusión

7,5 kg (dependiendo del filamento)

Extrusión (basada en la existente)

600mm 3 /min (dependiendo de los filamentos)

Paso E

932/mm a 16 micropasos (se recomienda una calibración adicional)

Distancia de rotación del Klipper

3.433

Corriente de motor recomendada

800mA

Relación de transmisión

7:1

Circunferencia del engranaje impulsor

24,5 mm

Diámetro y tolerancia del filamento

1,75 ± 0,05 mm

Tipo de termistor

NTC100K

Energía del cartucho del calentador

40W

Voltaje del cartucho calentador

24V

*Nota: No es compatible con el motor NEMA14 estándar.

Manual de usuario de vista rápida

*Nota: Solo necesita un soporte de modelo, H2 V2S es adecuado para casi todas las impresoras 3D más vendidas. Aquí están los archivos de B1, Artillery X1 Genius, Pedro Palacio, CR10-S Pro v2, Ender 3/3 V2, Ender 5, Ender 6, Anycubic Mega, CR-10 V2/V3, Creality CR-6